General

A rubber ball sieve cleaner(rubber ball) is a device or tool used to clean and maintain vibrating screens or sieves. Vibrating screens are commonly used in various industries to separate and classify different materials based on their size. Over time, the mesh or screen of the vibrating sieve can get clogged with particles, reducing its efficiency and affecting the screening process.

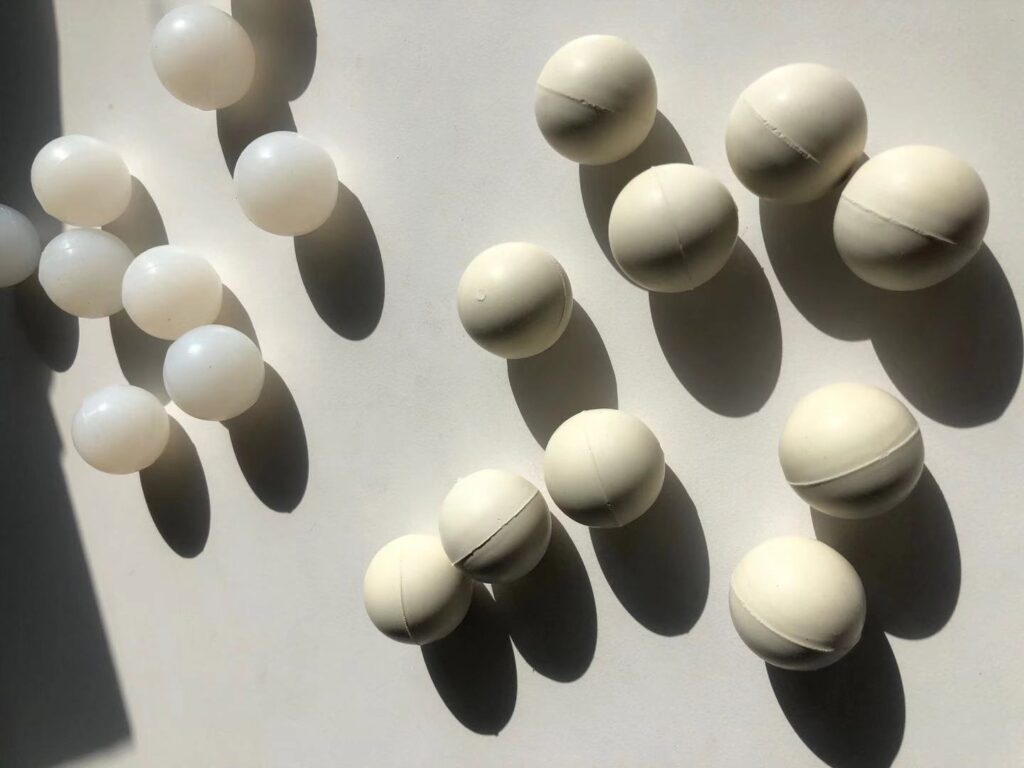

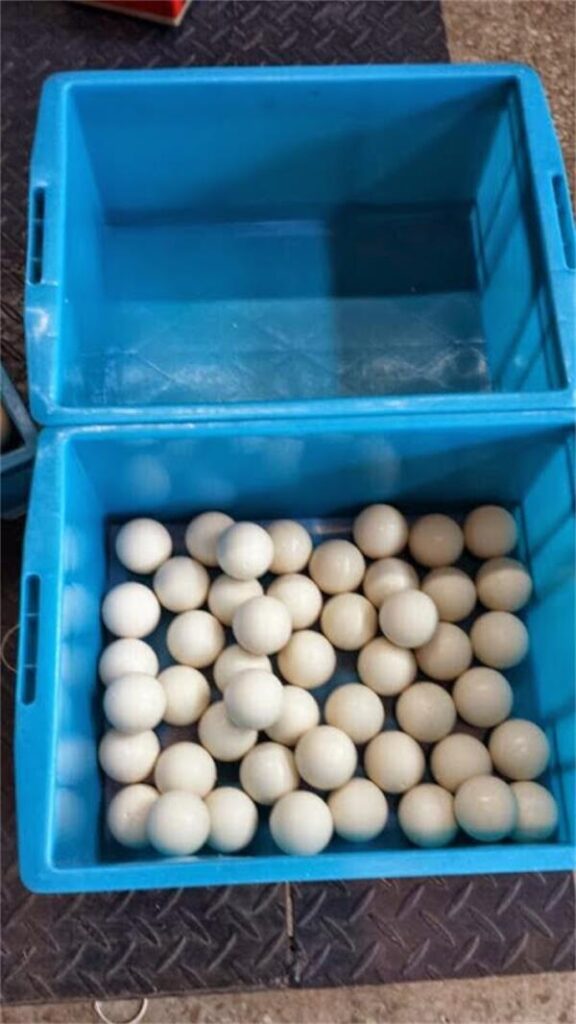

The rubber ball sieve cleaner is designed to prevent or remove blockages in the mesh of the vibrating screen. It typically consists of rubber balls that are placed on the top surface of the screen or within the screen’s layers. When the vibrating screen is in operation, these rubber balls bounce and move against the screen’s mesh, dislodging and clearing any stuck or trapped particles.

The purpose of using rubber balls for cleaning is to avoid damaging the mesh while effectively removing debris, particles, and materials that may adhere to the screen surface. This cleaning process ensures that the vibrating screen operates at its optimal capacity, maintaining high screening efficiency and preventing downtime for manual cleaning.

Rubber ball sieve cleaners are a vital component in vibrating screens, contributing to the smooth operation and longevity of screening equipment in various industries such as mining, construction, agriculture, and recycling.

Material

Natural rubber, silicone rubber and PU

Size

16mm, 19mm, 22mm, 24mm, 26mm, 28mm, 30mm, 32mm, 35mm, 38mm, 40mm, 50mm

Yutung produces the rubber ball, above is the standard.

Use Life

1 to 2 years. Rubber balls and silica gel balls are indispensable accessories for vibrating equipment. Rubber balls play a vital role in the operation of vibrating screens. They mainly imitate manual slapping on the screen surface to achieve the effect of not blocking the net. They belong to vibrating screens. The wearing parts in it are recommended to be replaced every 1 to 2 years.

YT Conveyor produces the rubber ball, send us an inquiry to lucyliu1976@gmail.com