SR2 Standard Rotary Paddle Bin Level Switch

Working Principle of the Silo Bin Level Switch

Our standard rotary paddy level silo bin switch sensor uses the electric motor to make the blade paddle revolve. When the medium materials arrive at the paddle blade position, the blade stops rotation to the impediment of the medium material. It is made by a related control devise to let the outputs open/pass or let it close/break by the electronic contact signal.

When the medium material drops and leaves the blade paddle, under the spring function, the blade paddle restores to the original position and rotates to monitor the variation position of the medium materials.

Feature of the Rotary Paddle type of Level Switch

- Use the rotary paddle blade switch technology to detect the bulk solid materials.

- Has the precision integrated mechanical seals to prevent incoming dust along the shaft;

- It has a unique spring clutch structure; when the blade paddle is overloaded, the automatic protection of the electric motor will be started.

- In the complete separation structure design, the whole level switch will not be dismantled completely when in maintenance.

- For the low-density material operation, we have a specially customized paddle type.

- Use the simple connection part; easy to install.

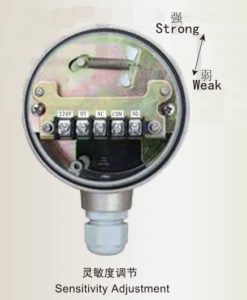

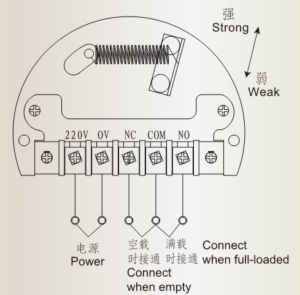

Technical Parameter of our Standard Rotary Paddle Level Switch

- Voltage: 220VAC, 110VAC, 24VAC and 24VDC

- Contact Capacity: 250VAC/5A (Negative Load), SPDT (Single Pole Double Throw)

- Work Temperature: -30℃-80℃; our common high-temperature type can reach 200℃, and for the special customized high-temperature type, it can even reach 800℃.

- Powder: 3W

- Rotating Torque: 1N.M

- Blade Paddle Rotational Speed: 1RPM

- Blade Paddle Material: SUS304

- Protection Grade: IP65

- Wire Outlet: M20x1.5

- Suitable the Material Density: >=0.4g/cm3

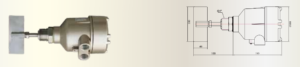

SR2-10S Rotary Paddle Level Switch

Standard Screw Type

Vertical and Horizontal Installation both Acceptable

SR2-10F Rotary Paddle Level Switch

Standard Flange Type

Vertical and Horizontal Installation both Acceptable

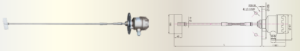

SR2-20F Rotary Paddle Level Switch

Axis Protection Tube Type

Vertical and Horizontal Installation both Acceptable

SR2-20F-T Rotary Paddle Level Switch

Axis Protection Tube and High-Temperature Type

Vertical and Horizontal Installation both Acceptable

SR2-30F Rotary Paddle Level Switch

Adjustable Axis Length Type

Only for Vertical Installation

SR2-40F Rotary Paddle Level Switch

Steel Cable Type

Only for Vertical Installation

SR2-20F-H Rotary Paddle Level Switch

Special High-temperature Type (Max 800℃)

Vertical and Horizontal Installation both Acceptable

SR2-10XLT Rotary Paddle Level Switch

Specially Customized

Vertical and Horizontal Installation both Acceptable

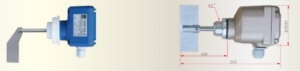

SR7-10 Rotary Paddle Level Switch

Standard Explosion Proof Type

Vertical and Horizontal Installation both Acceptable

SR2-10F-L Rotary Paddle Level Switch

Straight Rod Extension Type

Only for Vertical Installation

SR2-XLT Rotary Paddle Level Switch

Special Square Shape, Standard Screw Type

Vertical and Horizontal Installation both Acceptable

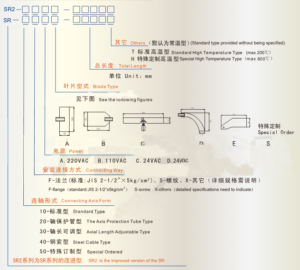

Model No. Selection Illustration:

For Example SR2-10SAA-0800

Means: Standard Screw Type, 220VAC, A Type 100x40mm Rotary Paddle, total length 800mm.

Application Places:

Applicable to the manufacturing and processing equipment in the industrial grain, feed, seed, cement, plastics processing, basic engineering, chemicals etc.

Installation Precaution of the Level Switch of the Grain Bin

- Please confirm the power supply during installation to avoid damage to the motor.

- During installation, keep away from the inlet to prevent material impact.

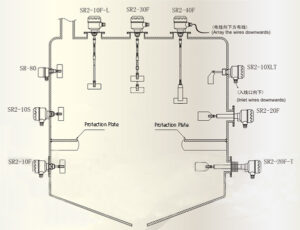

- During horizontal installation, please make sure the wire inlet is downwards; During vertical installation, please make the wires downwards (refer above diagram) and fasten the inlet connector and the upper cover of the junction box in case the rainwater and other foreign matters incoming, and then affect the use of our product.

- During horizontal installation, can install the level switch downward at about the angle of 15-20 degrees to reduce the accumulation of materials.

- When the level switch is installed in a lower position, please install the protection plate; see the above diagram. Can use the half round tube at least 50mm longer than the level switch length, fixed or welded on the right top 250mm position of the level switch.

Related Products for Bin/Silo

- RF Admittance Sensor

- Rotary Paddle Level Switch

- Rotary Paddle Level Switch

- Radar Sensor

- Sensing Weight Level Sensor

- RF Admittance Level Sensor

- Digital Displayer

- Small Rotary Paddle Level Switch

- Rotary Paddle Level Switch

- Capacitance Sensor Level Switch

- Pneumatic Hammer

- Pneumatic Vibrator