Application

The bucket elevator is a reliable and proven solution in multiple applications for high transportation requirements. Our bucket elevator considers the most rigorous quality and design standards for manufacturing. And the manufacturing design standards are according to the most demanding international regulations, whether for agricultural or industrial applications.

We design the bucket elevator which can be self-operated or be suitable for placing inside a support silo or tower.

Working capacities can be up to 1500 tons/hour.

The drive and return heads of the bucket elevator are robustly built. And the areas where they rub against the material are lined with specific anti-wear materials for each use.

They have relief mouths; the size is according to current NFPA Standards.

The case is made by SAE1010 steel, galvanized sheet steel, or stainless steel depending on the demands or application. The bucket elevator offers high wear resistance with abrasive materials.

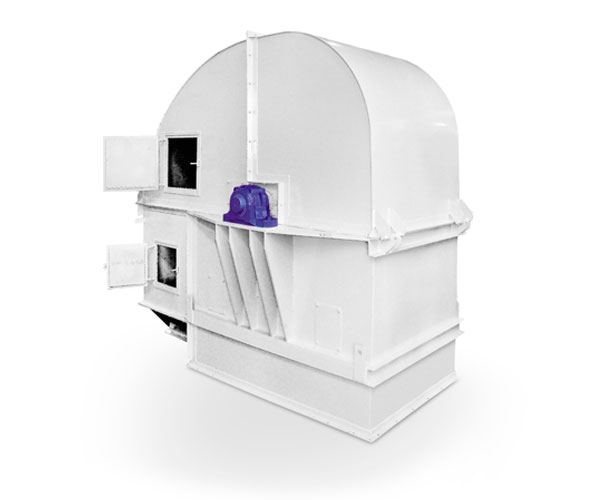

Drive head

The components of the control head – upper casings, discharge hopper, and body/structure – are linked by means of bolts. This makes it completely disassembled and allows full access to the drive drum. On the other hand, all the parts exposed to wear contact surfaces are covered with different anti-wear materials for this purpose, such as polyurethanes, hard steels, or ceramics.

YT conveyor manufactures bucket elevator components in China, like elevator HDPE and Steel buckets, elevator PVC belts, elevator fang bolts, head drum pulleys, and lagging materials for drum pulleys.

Tensioning head

Like the drive motorheads, the construction of the elevator foot respects the basic quality standards, such as the SN boxes for bearing support, and the calculation of the axes.

The access and inspection door are easy to be operated. The design of the loading port is very important according to the characteristics of the material to be lifted.